Time-of-Flight

Time-of-Flight

Compared to the other 3D techniques, Time-of-Flight (ToF) is the most suitable for applications that need flexibility in operation. For example, a ToF system can be mounted on a moving robot or used for measuring changing distances using its factory calibration (depending on the setup). The system can also be adapted to any operational setup making a ToF system well suited for use in complex environments and conditions.

Time-of-Flight is also the best candidate for applications where you have fast moving scenes and need reliable real-time decisions at several distance ranges (including long distances). With ToF systems, no heavy computation is required that may lead to latency and less detection accuracy of a non-determined scene. Our ToF systems provide real time image information with fast response times and no motion blur. They are also robust, compact and cost effective since they are a solid-state design, which uses less power and requires less computation.

A Time-of-Flight imaging system emits pulses of IR light and measures how long the light reflected from the objects in the scene takes to come back to the system.

In the case of an indirect ToF imaging system, the system measures the distance by calculating the phase differences of the light waves when they are emitted to the object and when they bounce back. This allows the system to build a 3D map. ToF systems provide users with a greater amount of information in a wide range of challenging conditions for a variety of applications.

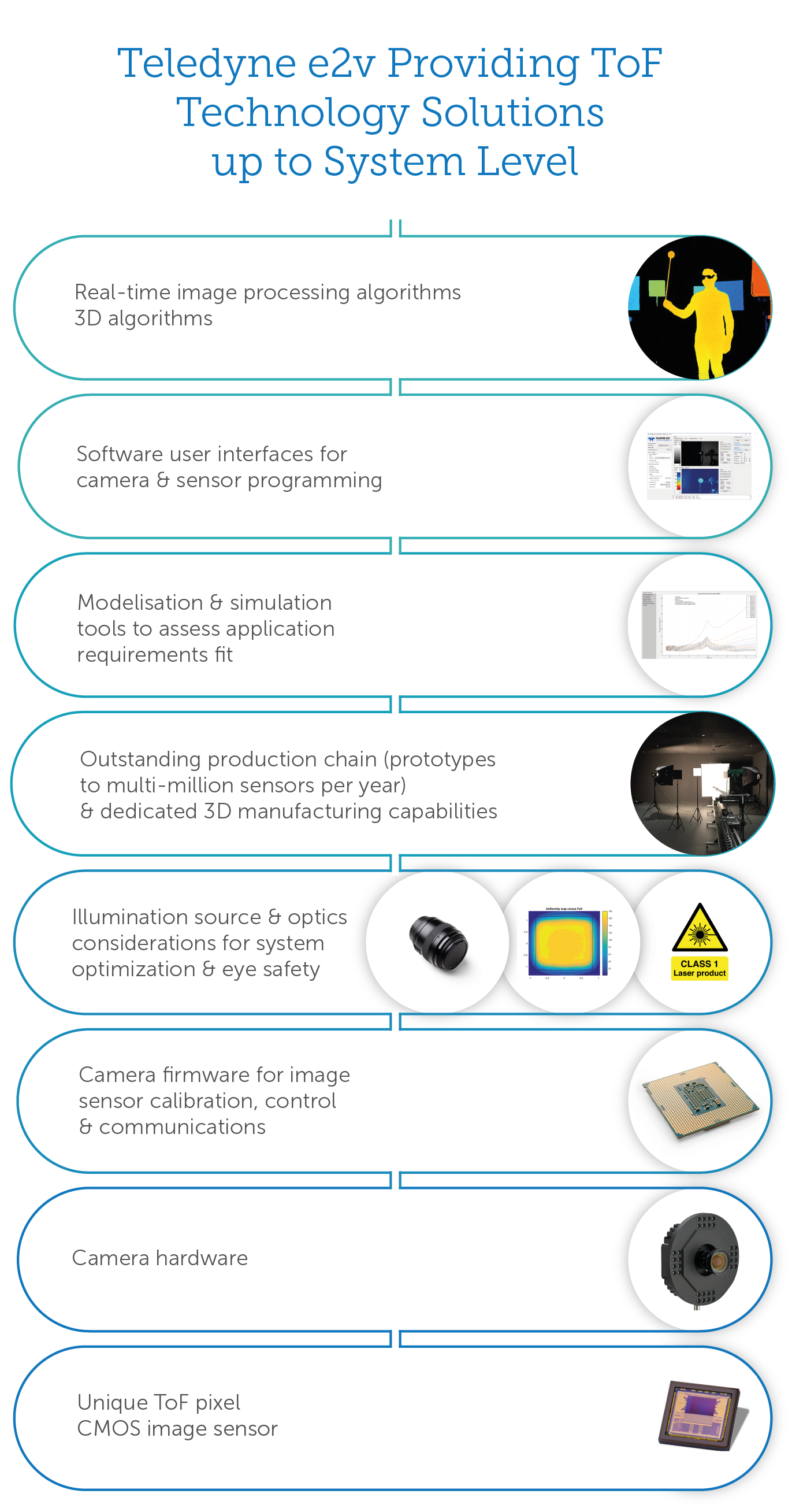

With over 10 years of Time-of-Flight experience, Teledyne e2v provides customers with technology solutions ranging from: CMOS image sensors and customised camera modules, right up to full system integration support. This includes a reference design of our evaluation platform, all system-level dimensioning, light & optics assessment, eye safety consideration, modelisation and simulations, algorithms and calibrations. This helps customers to shorten their time-to-market and get the best ToF system to fit their application requirements.

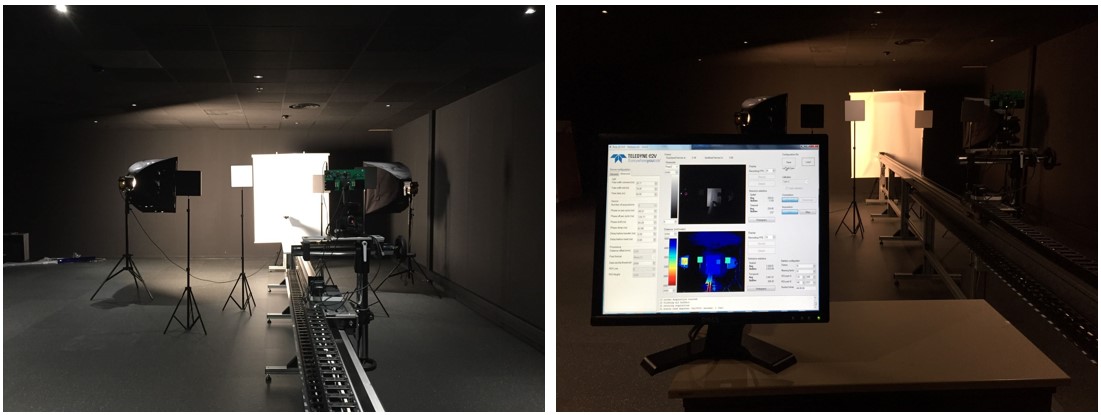

At our Grenoble site, we have developed a laboratory specifically dedicated to 3D Time-of-Flight sensors and systems. This is a fully compliant laser safe 100m² dark room which is coated to avoid reflection in NIR & visible light. Among other key elements, it’s equipped with a software controlled 10m motorized bench, a set of calibrated targets, and a specific illumination source to emulate operation under direct sunlight. The 3D Innovation Lab is used to perform live demos for customers and to characterize and calibrate our 3D Time-of-Flight sensors and systems. It is also essential to emulating application-level test cases, so we can effectively validate our customers’ requirements as well as developing and contributing to the standardization of distance measurements based on ToF techniques.