Laser Triangulation

Laser Triangulation

Compared with other 3D techniques, laser triangulation is the most suitable for applications that need very high accuracy (down to a micrometer) and very high speed. The camera can be in movement (e.g. when the camera is held by a robot or by a person), or fixed and the object be in movement (e.g. when inspecting pieces that are on a conveyor belt).

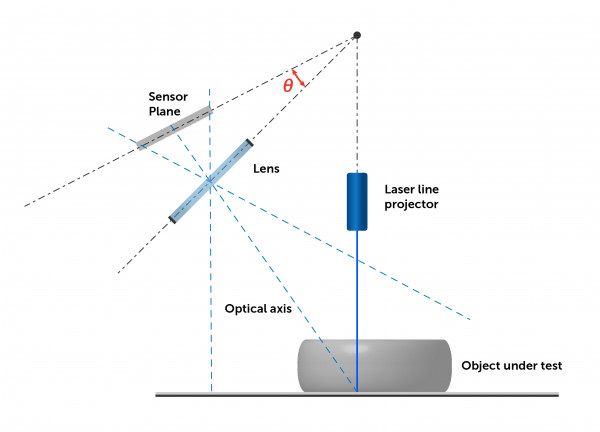

The object that we want to inspect is moving along the Y-axis and is scanned by the camera. A laser line is projected onto the object perpendicular to this axis and the laser profile that is formed is imaged in a 2D pixel array for each scan. Due to the different heights of different parts of the object, combined with the angle between the laser and the camera, the laser line is “distorted” into a laser profile when projected onto the object. In each image (which represents a 3D slice in the Y direction of the object), the row within every column (X) represents the height (Z) of the object at that point.

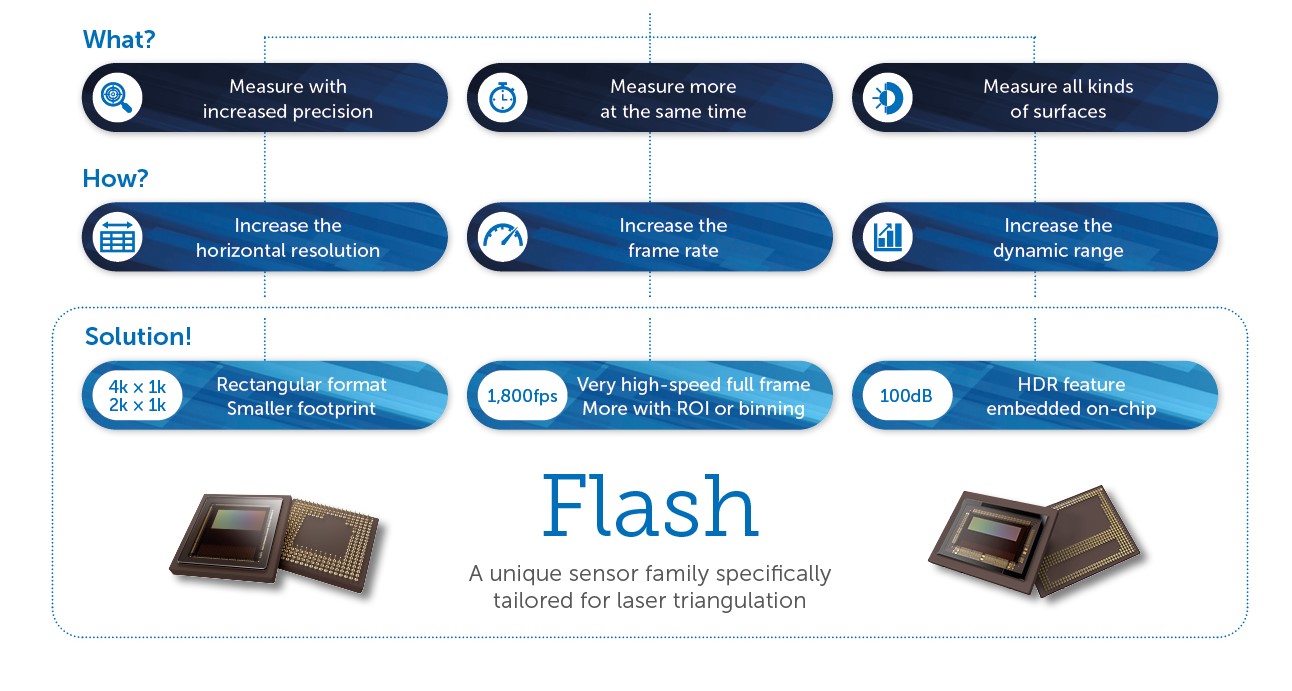

Teledyne e2v has over 20 years of experience in designing sensors for laser triangulation applications. We provide standard off-the-shelf sensors (such as Flash) to market leading camera manufacturers, as well as custom sensors, specifically designed for their individual needs. Derivatives are also possible on standard sensors, both at soft and hard levels, to enable differentiation. Some examples are listed below, but additional derivatives are available on demand.

There is, for example, the possibility to increase the full well capacity of the pixels, or to use a low power mode that can trade-off the frame rate with the number of LVDS and the power consumption, e.g. if you want to use less LVDS or if the power consumption is important for your application.

There is the possibility to add a custom color filter array or a custom micro-lens array onto the sensor. Another derivative that we offer is with regard to the Scheimpflug angle. Laser triangulation normally requires that the optical system is not perpendicular to the sensing plane, but tilted to a certain angle (as shown below). This is called the Scheimpflug principle, which implies a loss of signal due to the angular response of the sensor which can be quite significative when angles are large. This can be compensated for through a simple derivative specifically adapted for the angle you use in your application.

Join Yoann Lochardet, Marketing Manager for 3D Image Sensors at Teledyne e2v, in this webinar about laser triangulation. Yoann explains the concept, how it works, the challenges and how to overcome them.

Downloads